ABS

ABS 〈Acrylonitrile Butadiene Styrene〉 is a thermoplastic polymer material with high strength, good toughness and easy processing. ABS resin can be blended with a variety of resins into a blend, such as PC / ABS, ABS / PVC, PA / ABS, PBT / ABS, etc., to create new performance and new applications field.

Use:

Applicable to household appliances, such as TV housings, refrigerator linings, vacuum cleaners, etc., as well as meters, telephones, and plastic products for the automotive industry.

Color: Black, White, Yellow (Origanal)

Characteristic:

>good appearance and physical properties

>less molding shrinkage

Use:

Applicable to household appliances, such as TV housings, refrigerator linings, vacuum cleaners, etc., as well as meters, telephones, and plastic products for the automotive industry.

Color: Black, White, Yellow (Origanal)

Characteristic:

>good appearance and physical properties

>less molding shrinkage

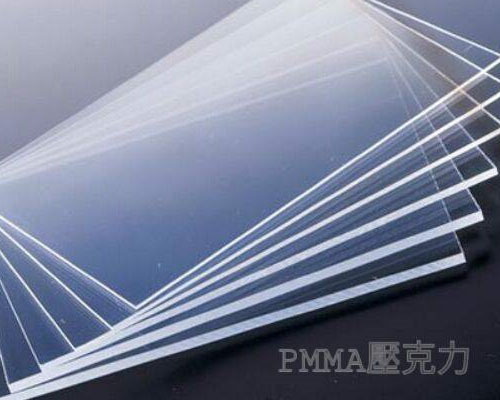

PMMA

Acrylic 〈Poly (methylmethacrylate) or Lucite〉

has the advantages of high transparency, low price, easy machining, etc. , also a glass substitute material is used frequently.

Use:

Applicable to all kinds of medical equipment, bathroom facilities, handicrafts, cosmetics, brackets, aquariums, light boxes, signboards, display racks, etc.

Color: Black, White, Transparent (able to dyeing)

Characteristic:

>excellent transparency

>high-quality lustrous surface

Use:

Applicable to all kinds of medical equipment, bathroom facilities, handicrafts, cosmetics, brackets, aquariums, light boxes, signboards, display racks, etc.

Color: Black, White, Transparent (able to dyeing)

Characteristic:

>excellent transparency

>high-quality lustrous surface

PC

PC 〈Polycarbonate〉 is a colorless and transparent amorphous thermoplastic metarial.

Use:

Suitable for mechanical parts such as gears, auto parts, electrical tool housings, parts and camera bodies, transparent food cans, bulletproof glass, doors and windows in public places, outdoor lighting covers, protective helmets, as well as the windshield, canopy and instrument panel of the aircraft. PC can be blended with glass fiber (GF) to create new performance and new applications field.( The proportion of GF affects hardness and brittleness)

Color: Black, White, Transparent

Characteristic:

>strong toughness, impact resistance

>excellent heat resistance

>transparent

Use:

Suitable for mechanical parts such as gears, auto parts, electrical tool housings, parts and camera bodies, transparent food cans, bulletproof glass, doors and windows in public places, outdoor lighting covers, protective helmets, as well as the windshield, canopy and instrument panel of the aircraft. PC can be blended with glass fiber (GF) to create new performance and new applications field.( The proportion of GF affects hardness and brittleness)

Color: Black, White, Transparent

Characteristic:

>strong toughness, impact resistance

>excellent heat resistance

>transparent

PC+ABS

PC+ABS combines the excellent properties of two materials, the formability of ABS materials and the mechanical properties of PC, impact strength and high temp resistance, and resistance to ultraviolet (UV).

Use:

Applicable to instrument panel, instrument front cover, interior and exterior decoration, notebook, electronic product casing, meter cover, household switch, electrical and internal parts.

Color: Black

Characteristic:

>high processability

>toughness stable

>high temp resistance

Use:

Applicable to instrument panel, instrument front cover, interior and exterior decoration, notebook, electronic product casing, meter cover, household switch, electrical and internal parts.

Color: Black

Characteristic:

>high processability

>toughness stable

>high temp resistance

POM

POM 〈Polyoxymethylene〉 is a thermoplastic used in engineering for high rigidity, low friction and excellent dimensional stability.

Use:

It can replace most non-ferrous metals, automobiles, machine tools, instrument parts, bearings, gears, springs, pipes, transport belt parts, sprinklers, faucets, etc.

Color: Black, White

Characteristic:

>high hardness, excellent crocking resistance

>high heat resistance

>low water absorption

Use:

It can replace most non-ferrous metals, automobiles, machine tools, instrument parts, bearings, gears, springs, pipes, transport belt parts, sprinklers, faucets, etc.

Color: Black, White

Characteristic:

>high hardness, excellent crocking resistance

>high heat resistance

>low water absorption

AL

AL 〈Aluminum〉 usually use alloying elements such as copper, zinc, manganese, silicon, and magnesium, they are lighter and more resistant to corrosion than ordinary carbon steel, but they are less corrosion resistant than pure aluminum.

In a clean, dry environment, a protective oxide layer is formed on the surface of the aluminum alloy. The price of aluminum is higher than that of iron and steel, but it is easy to recycle and remelted, it is the most environmentally friendly metal material.

Use:

Suitable for utensils, lids, handles, brackets, ladders, strollers, printing plates, decorations, curtain walls, canopies, roofs, electrical appliances, vehicle structures, skates, ship structures, decks

Color: Metal original color

Characteristic:

>heat resistant,excellent wear resistance

>light texture, corrosion resistant

>excellent heat conduction

Use:

Suitable for utensils, lids, handles, brackets, ladders, strollers, printing plates, decorations, curtain walls, canopies, roofs, electrical appliances, vehicle structures, skates, ship structures, decks

Color: Metal original color

Characteristic:

>heat resistant,excellent wear resistance

>light texture, corrosion resistant

>excellent heat conduction

CU

CU 〈Copper〉 , pure copper is a soft metal with reddish-orange metallic luster, good ductility, high thermal conductivity and high electrical conductivity. Therefore, it is the most commonly used material in cable and electrical and electronic components, and can also be used as building materials, and a variety of alloys.

Copper alloys have excellent mechanical properties and low electrical resistivity, the most important of which are bronze and brass.

In addition, copper is also a durable metal that can be recycled multiple times without compromising its mechanical properties.

Use:

Applicable to electrical appliances, sanitary parts, valves, mechanical parts, bearings, gears, marine parts, decorations, vehicle structures, etc.

Color: Red, Yellow, bronze

Characteristic:

>excellent ductility, excellent gold plating

>excellent crocking resistance, good corrosion resisting

>excellent thermal conductivity and electrical conductivity

Use:

Applicable to electrical appliances, sanitary parts, valves, mechanical parts, bearings, gears, marine parts, decorations, vehicle structures, etc.

Color: Red, Yellow, bronze

Characteristic:

>excellent ductility, excellent gold plating

>excellent crocking resistance, good corrosion resisting

>excellent thermal conductivity and electrical conductivity

Zinc

Zinc alloys are alloys based on zinc and added to other elements. Commonly added alloying elements are aluminum, copper, magnesium, cadmium, lead, titanium, etc.

Zinc alloy has low melting point, good fluidity, easy fusion welding and plastic processing. It is resistant to corrosion in the atmosphere, and the residual waste is easy to recover and remelted, but the creep strength is low, therefore, it is prone to natural aging and cause dimensional changes.

According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. The main added elements of zinc alloys are aluminum, copper and magnesium.

Acording to the processing technology, it can be divided into two types: deformation and cast zinc alloy. Cast zinc alloys have good fluidity and corrosion resistance.

Use:

Suitable for consumer electronics(3C prodoucts), hardware, parts of automobilies and scooters, bicycle parts, etc.

Color: Red, Yellow, bronze

Characteristic:

>easy to mold, high processability

>good mechanical properties at normal temperature, excellent crocking resistance

>good casting performance

Use:

Suitable for consumer electronics(3C prodoucts), hardware, parts of automobilies and scooters, bicycle parts, etc.

Color: Red, Yellow, bronze

Characteristic:

>easy to mold, high processability

>good mechanical properties at normal temperature, excellent crocking resistance

>good casting performance

PEEK

PEEK 〈 polyetheretherketone 〉 is resistant to almost all organic and inorganic chemicals due to its excellent high temperature resistance (melting point of 335 ° C). Today, PEEK is the premier thermoplastic high-performance project, and PEEK is the ideal material for a wide range of applications, such as the aerospace industry, automotive, and electronics and semiconductor technologies. PEEK is biocompatible and can be sterilized and sterilized by X-rays, making it widely used in the medical field. In the pharmaceutical and food industries, PEEK can be used for parts that come into contact with the product.

Use:

Used in aerospace, automotive, electronics, energy, medical, and industrial industries.

Color: Black

Characteristic:

>high temperature resistance, excellent crocking resistance, high cleanliness, chemical resistance, radiation resistant, hydrolysis resistance, electrical characteristics, fire resistance, low smog characteristic

Use:

Used in aerospace, automotive, electronics, energy, medical, and industrial industries.

Color: Black

Characteristic:

>high temperature resistance, excellent crocking resistance, high cleanliness, chemical resistance, radiation resistant, hydrolysis resistance, electrical characteristics, fire resistance, low smog characteristic

PP

PP 〈Polypropylene 〉 is a semi-crystalline thermoplastic with high impact resistance, strong mechanical properties, resistance to various organic solvents and acid-base corrosion, and is widely used in industry.

PP is a non-toxic, odorless, tasteless, milky white high crystalline polymer with a density of only 0.90--"0. 91g/cm3, which is one of the lightest varieties of all plastics. It is particularly stable to water, and its water absorption in water is only 0.01%, and the molecular weight is about 80,000 to 150,000. The moldability is good, the shrinkage rate is large (1% to 2.5%), and the surface gloss of the product is good.

Use:

Applicable to automotive, electrical, mechanical, instrumentation, radio, textile, defense engineering accessories, daily necessities, turnover boxes, medical and health equipment, building materials, etc.

Color: White

Characteristic:

>high chemical resistance, high strength, high hardness

>good mechanical efficiency

>hard wearing,good surface slidability

>excellent formability, mechanical strength is better than PE

> water resistance, chemical resistance, good electrical insulation

> chemical resistant acid and alkali

Use:

Applicable to automotive, electrical, mechanical, instrumentation, radio, textile, defense engineering accessories, daily necessities, turnover boxes, medical and health equipment, building materials, etc.

Color: White

Characteristic:

>high chemical resistance, high strength, high hardness

>good mechanical efficiency

>hard wearing,good surface slidability

>excellent formability, mechanical strength is better than PE

> water resistance, chemical resistance, good electrical insulation

> chemical resistant acid and alkali

Rubber

Rubber refers to a highly elastic polymer material with reversible deformation. It is elastic at normal temperature and can be deformed under a small external force. It can be restored to the original state after removing external force.

Rubber is a completely amorphous polymer with a low glass transition temperature (Tg) and a large molecular weight.

The early rubber is taken latex from plants such as rubber trees and rubber grass, and is made of a material having elasticity, insulation, impermeable. It is a highly elastic polymer compound, divided into two kinds of natural rubber and synthetic rubber.

Natural rubber is processed by refined gum from plants such as rubber trees and rubber grasses, synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industrial or life aspects.

Use:

Suitable for buttons, pads, aerospace use, protective equipment, industrial applications, machinery industry, electronics, medical, chemical industry, construction industry, automotive industry, etc.

Color: Milk White

Characteristic:

>good anti-elasticity, good wear resistance, good resistance to bending and cracking, good puncture resistance and good low temperature resistance. Slip resistance, tearing force, good pulling force, soft material.

Use:

Suitable for buttons, pads, aerospace use, protective equipment, industrial applications, machinery industry, electronics, medical, chemical industry, construction industry, automotive industry, etc.

Color: Milk White

Characteristic:

>good anti-elasticity, good wear resistance, good resistance to bending and cracking, good puncture resistance and good low temperature resistance. Slip resistance, tearing force, good pulling force, soft material.

Nylon

Nylon is a man-made polymer, fiber, plastic, and its constituent units are connected by guanamine.

Nylon is the world‵s first fully man-made fiber. The raw materials are coal, water and air. From these raw materials, two basic chemicals, hexamethylenediamine and adipic acid, are mixed together to form nylon.

Use:

Suitable for buckle belts, car seat belts, ropes, brushes, safety tire mesh inner layer, travel backpack, luggage, mattress, plastic gear, plastic tube, medical supplies and equipment, etc.

Color: Black, White

Characteristic:

>high chemical resistance, high strength, high hardness, good aging resistance and good wear resistance.

Use:

Suitable for buckle belts, car seat belts, ropes, brushes, safety tire mesh inner layer, travel backpack, luggage, mattress, plastic gear, plastic tube, medical supplies and equipment, etc.

Color: Black, White

Characteristic:

>high chemical resistance, high strength, high hardness, good aging resistance and good wear resistance.

Bakelite

Bakelite is a resin prepared by polycondensation, neutralization and water washing of phenol and formaldehyde under catalyst conditions, among which phenol and formaldehyde resins are the most important.

The solid phenolic resin is a yellow, transparent and amorphous bulk material. It is reddish due to the free phenol. The solid specific gravity is about 1.7. It is easily soluble in alcohol, insoluble in water, and stable to water, weak acid and weak alkali solution.

It is also the first polymer material in the world that has been artificially synthesized and still important today.

Use:

Applicable to daily necessities such as handles, electronic test boards, tool machinery pads, structural parts, mold insulation boards, etc.

Color: Tangerine, Black

Characteristic:

>high temperature performance, high bond strength, high residual carbon ratio, low smoke, low toxicity, chemical resistance, good heat treatment, good mechanical strength, wear resistance

Use:

Applicable to daily necessities such as handles, electronic test boards, tool machinery pads, structural parts, mold insulation boards, etc.

Color: Tangerine, Black

Characteristic:

>high temperature performance, high bond strength, high residual carbon ratio, low smoke, low toxicity, chemical resistance, good heat treatment, good mechanical strength, wear resistance